如何解决钢化玻璃自爆问题?世界杯今日赛程表

加纳vs乌拉圭预测

原始

2017-07-10 15:53:38

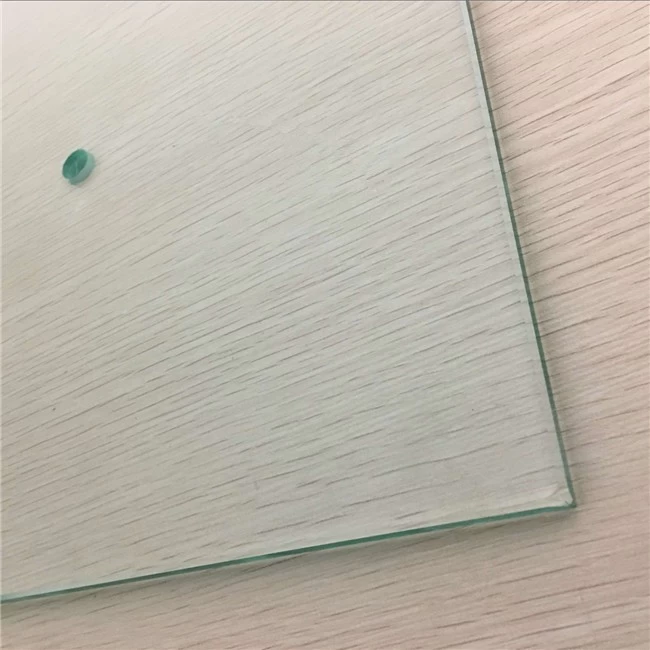

世界杯今日赛程表钢化玻璃是一种安全玻璃,通过控制热处理或化学处理来提高其强度,与普通玻璃相比。为了提高玻璃的强度,我们通常采用化学或物理方法在玻璃表面形成压应力。玻璃在受到外力作用时,表面应力先被抵消,承载能力不断提高。世界杯今日赛程表钢化玻璃作为建筑工业中最重要的建筑材料之一。当我们在想着它的优点的时候,我们也担心钢化玻璃的自爆。世界杯今日赛程表

钢化玻璃世界杯今日赛程表为什么会自爆?

-影响玻璃质量的缺陷,玻璃中有结石、杂质、气泡:玻璃杂质是钢化玻璃的薄弱,也是应力集中。世界杯今日赛程表特别是如果石材处于钢化玻璃的拉伸区域是导致爆裂的重要因素。世界杯今日赛程表

-钢化玻璃内部应力分布不均匀,存在偏移。世界杯今日赛程表在加热或冷却过程中,玻璃在玻璃厚度方向上的温度梯度是不均匀和不对称的。以至于产品开花的趋势,有些在寒冷的时候被“风吹破”。如果拉伸区域移到物品的一侧或偏移到表面,则钢化玻璃被吹制。世界杯今日赛程表

-钢化程度,实验证明,当钢化程度达到1 / cm时,自爆次数高达20% ~ 25%。这说明应力越大,锥度越大,自爆量越大。

如何解决钢化玻璃自爆问题?世界杯今日赛程表

降低应力值和应力均匀均可解决钢化玻璃自爆问题,但最好的方法是热浸。世界杯今日赛程表热浸处理,又称均质处理。热浸处理是将钢化玻璃加热到290℃±10℃并保温一定时间。世界杯今日赛程表使硫化镍在钢化玻璃中迅速完成晶体相变。世界杯今日赛程表减少安装后钢化玻璃的使用。世界杯今日赛程表这种方法一般使用热空气作为加热介质。我们称之为“热浸试验”,简称HST,直译为热浸处理。从原理上看,热浸处理既不复杂也不困难。但实际上要实现这个过程是非常困难的。研究表明,玻璃中的硫化镍有多种化学式。 Such as Ni7S6, NiS, NiS1.01 and so on. Not only the proportion of various components, and also may be doped with other elements. The phase change is highly dependent on the temperature level. Studies have shown that the rate of phase change at 280 ° C is 100 times that at 250 ° C, so it is necessary to ensure that the glass in the furnace experiences the same temperature regime. Otherwise the low temperature of the glass on the one hand due to insufficient insulation time, nickel sulfide can not completely phase change, weakening the effectiveness of heat soak. On the other hand, when the glass temperature is too high, it may even cause reverse phase transformation of nickel sulfide, resulting in greater hidden dangers. Both of these conditions can lead to heat soak treatment and reactive and even counterproductive. The temperature uniformity of the heat soak furnace is so important. In fact, heat soak technology and equipment has been constantly improving. German standard DIN18516 in the 90 version of the provisions of the holding time of 8 hours, while the prEN14179-1: 2001 (E) standard will keep the insulation time down to 2 hours. The effect of the heat soak process under the new standard is very significant, and there is a clear statistical technical indicators. Heat soak can be reduced to 400 tons of glass per case blew. On the other hand, the heat soak furnace is also constantly improving the design and structure, heating uniformity has also been significantly improved, the basic can meet the requirements of heat soak process. Although the heat soak treatment can not guarantee that no blew does not occur, but reduce the occurrence of blew, real solution to the troubled works of the parties self-explosion the problem. So heat soak is the world's unanimous endorsement of the most effective way to solve the problem of self-explosion.